From dental devices to jet engines, 3D printing is quickly becoming mainstream. Its use is moving well beyond prototyping and toys, towards industrial applications. Leading the way in the commercialisation of industrial 3D printers is AML3D (ASX: AL3), and their market update today proves that they plan on staying ahead of the game.

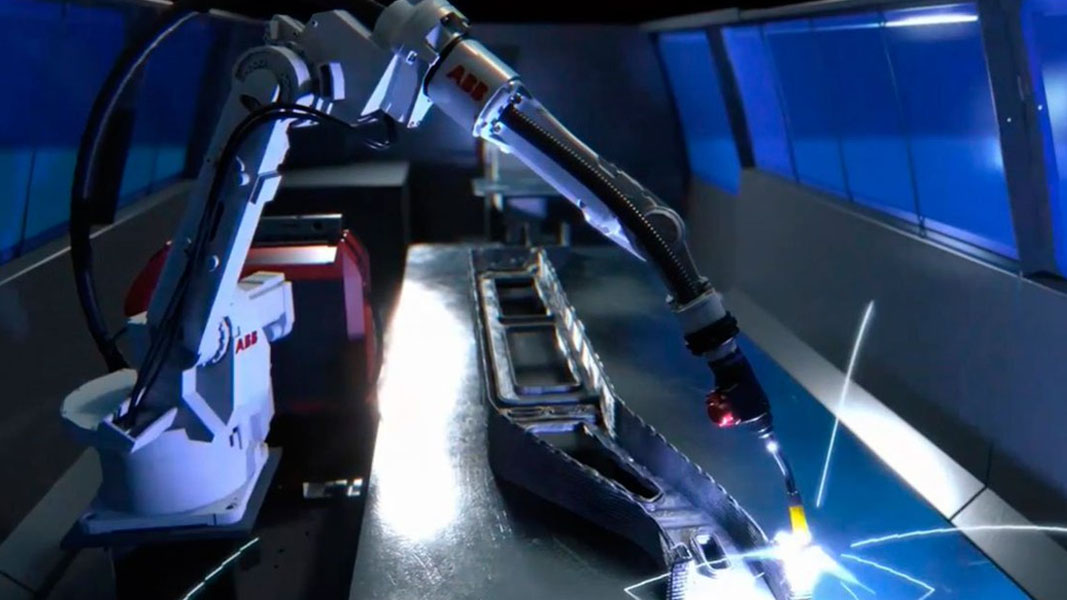

The Company specialises in large scale ‘Additive Metal Layering’ 3D printing, a process that allows printing of metal components of any size but is particularly useful for medium to large scale structures that require considerable strength and stability. The tech allows for manufacturing of cost effective, high quality parts and is applicable to almost any industry.

AML3D is currently in the process of developing its next generation ‘Arcemy’ printing units- the world’s largest certified 3D metal printer. The units have been a work in progress since early 2020.

With the conceptual hardware design recently completed the Company is now focusing on making their product even better.

Their next goal is to establish a high productivity printer that increases the printing rate with a deposition rate of five times the current amount. They are also simultaneously integrating finishing technology into their products that reduces post-production machining and finishing. Designs of the first hybrid printers are expected to be completed by Q1 FY22.

AML3D’s signature software WAMSoft® has received an update too with the latest version scheduled for release early next year. The Company has been working in conjunction with the CSIRO to design and implement new material strength prediction functionality into their proprietary software which will add to their already strong value proposition.

Andrew Sales, Managing Director is pleased with this progress and highlighted AML3D’s focus- to become “a world leader and staying at the forefront of innovation in additive manufacturing technology”

The global 3D printing market was valued at over USD $13 billion last year. The industry is expected to grow at an impressive rate of 26% over the next four years due to 3D printing’s appeal as a very attractive, viable alternative to conventional manufacturing techniques.

AML3D’s disruptive technology may well force the manufacturing industry to reevaluate their offering in order to keep up.

- Parkinson’s UK backs Pharmaxis with $5 million to slow the onset of incurable disease with ‘ground breaking’ trial - September 1, 2022

- How this company is developing medtech to support Indigenous community health - August 22, 2022

- A round of ap-paws for PharmAust, changing the ruff prognosis for dogs with lymphoma - August 17, 2022

Leave a Comment

You must be logged in to post a comment.